Ni Catalyst Activated Carbon

- Item No.

- NI

Catalytic Support for Hydrogenation and Chemical Reactions

NI is a functional activated carbon utilizing high-surface-area coconut shell-based material impregnated with nanoscale nickel (Ni) particles. Leveraging the catalytic properties of nickel, it delivers high performance in hydrogenation and various chemical reaction processes involving organic compounds.

Features

- High Catalytic Activity

- Nickel, as a transition metal, exhibits a reactive electronic structure that enables efficient catalysis, particularly in hydrogenation reactions.

- Nanoparticle Dispersion

- Uniform loading of nickel at the nanoscale enhances both reaction rate and catalyst durability, improving operational efficiency by approximately 30%.

- High-Quality Activated Carbon Base

- The large surface area of coconut shell activated carbon maximizes gas–solid contact, improving reaction efficiency and adsorption performance.

- Enhanced Durability

- Offers excellent structural stability and resistance to heat and chemicals, ensuring long service life under demanding conditions.

Our nickel catalytic activated carbon is activated carbon with nickel impregnated in nanoparticle state into a high-quality coconut shell activated carbon with excellent adsorption action. It possesses transition metal catalytic function.

Application

Gas Purification

Effective in the removal of harmful gases and volatile organic compounds (VOCs).

Hydrogenation Catalyst

Suitable for catalytic hydrogenation processes in industrial chemical synthesis.

Technical data

Ammonia adsorption limit performance comparison test

◆ Test overview

| Sample | A:Coconut shell activated carbon KD-GW 10g

B:Nickel catalytic activated carbon10g (Ni : KD-GW = 2 : 8) |

|---|---|

| Gas concentration | Ammonia 100ppm/time |

| Measurement time | 10 minutes/time |

| Detection tube | Gas Tech Ammonia No. 3La |

- (1) Place the sample in a polyethylene bag (200 x 300mm), put in air using an air pump, and seal the bag with a sealer.

- (2) Inject with a syringe the reagent with predetermined concentration.

- (3) Let stand for 10 minutes, then measure the ammonia concentration in the detection tube.

- (4) Repeat (1) to (4) to check for break points.

◆ Test results

| No. of times | A:Coconut shell activated carbon KD-GW | B:Nickel catalytic activated carbon | ||

|---|---|---|---|---|

| Input amount(ppm) | Measured value(ppm) | Input amount(ppm) | Measured value(ppm) | |

| 1 | 100 | 0 | 100 | 0 |

| 2 | 100 | 0 | 100 | 0 | s

| 3 | 100 | 0 | 100 | 0 |

| 4 | 100 | 0 | 100 | 0 |

| 5 | 100 | 0 | 100 | 0 |

| 6 | 100 | 0 | 100 | 0 |

| 7 | 100 | 0 | 100 | 0 |

| 8 | 100 | 0 | 100 | 0 |

| 9 | 100 | 0 | 100 | 0 |

| 10 | 100 | 0 | 100 | 0 |

| 11 | 100 | 0 | 100 | 0 |

| 12 | 100 | 0 | 100 | 0 |

| 13 | 100 | 0 | 100 | 0 |

| 14 | 100 | 0 | 100 | 0 |

| 15 | 100 | 0 | 100 | 0 |

| 16 | 100 | 5 | 100 | 0 |

| 17 | 100 | 7 | 100 | 0 |

| 18 | 100 | 10 | 100 | 0 |

| 19 | 100 | 10 | 100 | 0 |

| 20 | 100 | 12 | 100 | 0 |

| 21 | 100 | 12 | 100 | 0 |

| 22 | 100 | 15 | 100 | 0 |

| 23 | 100 | 18 | 100 | 0 |

| 24 | 100 | 20 | 100 | 0 |

| 25 | 100 | 22 | 100 | 2 |

| 26 | 100 | 25 | 100 | 5 |

| 27 | 100 | 40 | 100 | 4 |

| 28 | 100 | 42 | 100 | 5 |

| 29 | 100 | 38 | 100 | 5 |

| 30 | 100 | 50 | 100 | 5 |

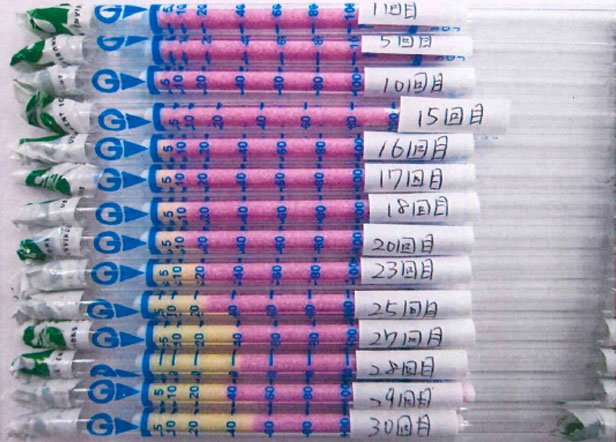

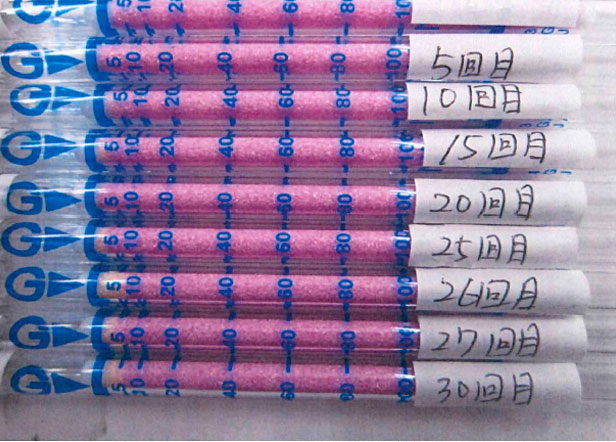

◆ Test result image

| A:Coconut shell activated carbon KD-GW | B:Nickel catalytic activated carbon |

|---|---|

|

|

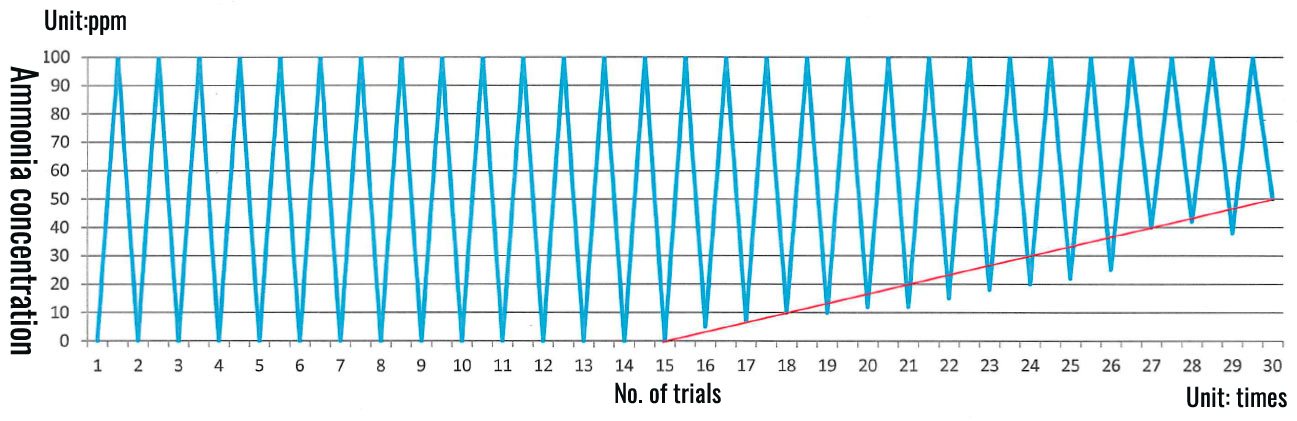

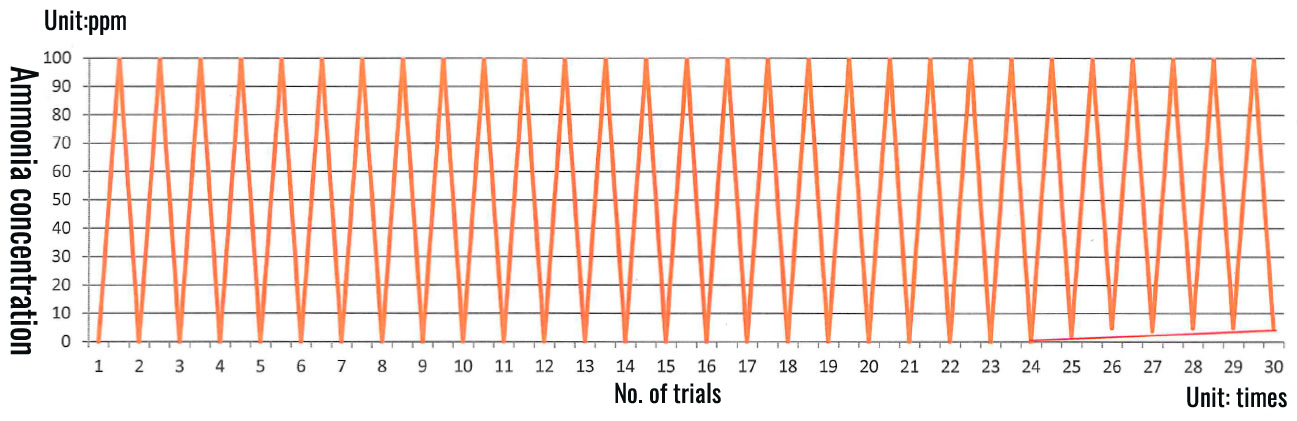

◆ Test resultsgraph

| A:Coconut shell activated carbon KD-GW |

|---|

|

| B:Nickel catalytic activated carbon |

|

Quality specifications(analysis example)

| Shape | Granular |

|---|---|

| BET surface area | 610.3㎡/g |

| Hardness | 98.5% |

| Particle size(MESH) | 20x50 |

| Packing density | 0.65g/㎤ |

| Ash content | 2.3% |

| Catalyst | Nickel |

| Loss on drying | 11.4% |

| Minimum Lot | 100㎏〜 |